Glass has an impact on almost all aspects of modern life. Glass is becoming an essential material for everything from the skyscrapers that dominate our cityscapes to the ubiquitous smartphone screen. Because of its special physical qualities, which include strength, malleability, transparency, and impermeability, glass is perfect for an astounding number of applications in a variety of industries. This article examines eight of the most popular and significant manufactured glass varieties and its applications.

1. Annealed Glass

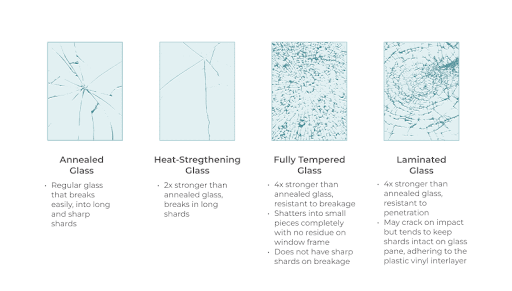

Annealed glass is one of the most popular and cost-effective types of manufactured glass. It is made by heating glass to a high temperature and allowing it to cool gradually and uniformly inside a furnace that is temperature-controlled and referred to as a “lehr.” This process removes internal stresses from the glass, making it less likely to crack or break. Although annealed glass is not as durable as tempered glass, it is still a very adaptable product that finds application in many different markets.

Why Is It Used?

Annealed glass is used for general-purpose applications that do not require high strength. It finds the optimum balance between affordability, durability, and practicality. During fabrication, annealed glass is easily cut, drilled, edged, tinted, and moulded. This makes it perfect for applications where greater durability is not necessary, such as table tops, framed glass panels, and small windows.

2. Heat Strengthened Glass

Heat strengthened glass is made by heating annealed glass to temperatures above 600°C and then rapidly cooling it. As a result, it becomes stronger and has 2-3 times higher heat resistance than ordinary annealed glass. Heat strengthening makes glass far more resistant to changes in temperature and wind pressure, even though it is still not as strong as fully tempered glass. Heat strengthened glass is commonly used when strength is needed but true safety glass is not required, such as in commercial building windows or vehicle side and rear windows.

Why Is It Used?

Compared to annealed glass, heat strengthened glass offers significantly greater strength and heat resistance and is simpler to drill, cut, and form into unique shapes than tempered glass. Because of these qualities, it is a good fit for applications requiring a little extra durability, such as building windows and car doors and rear windows.

3. Toughened Glass

Toughened glass, also known as tempered glass, is approximately 4-5 times stronger than annealed glass. It is formed by quickly cooling heated glass to produce tension in the centre and compression stresses on the surface. Its strength and safety have significantly increased as a result. Toughened glass is used for things like automobile windscreens, building windows, glass doors, glass tables and other things that need to be sturdy and safe because of its hardness and safety.

Why Is It Used?

Toughened or tempered glass has significantly increased strength and shatter-resistant properties. Its reliable durability makes it suitable for demanding applications. Tempered glass breaks safely into small, deadly shards and is more resilient to high wind loads and direct blunt force than other types of glass. Tempered glass is an essential material for applications such as vehicle windscreens and glass doors due to its safety features.

4. Laminated Glass

Laminated glass is made up of two or more glass layers joined by interlayers of vinyl or polyvinyl butyral. This holds the glass in place even when it is badly cracked or broken, preventing it from shattering into shards. Laminated glass is used in situations where safety from shattering and falling glass shards is critical. Its common uses include vehicle windshields, building windows and skylights, hurricane and security glass, bullet-resistant glass, and other specialty applications.

Why Is It Used?

Laminated glass provides a critical shield against glass shards in the event of breakage or cracking. Laminated glass is the industry standard for vehicle windscreens, bulletproof buildings, and other vital applications because it offers unmatched safety and security along with the optical clarity of glass.

5. Patterned Glass

Patterned glass has aesthetic textures or designs imprinted on one or both sides during manufacturing to change the way light scatters. Options for common patterns are ribbed, fluted, frosted, and other elaborate designs. Patterned glass works well for window privacy films, bathroom enclosures, room dividers, interior doors and other applications where both obscurity and decorative visual appeal are crucial.

Why Is It Used?

Patterned glass is a useful material for interior privacy applications such as bathrooms, conference rooms, doors, and partitions because it transmits light while blocking out unwanted views. Patterned glass has a decorative appeal that plain clear glass cannot match due to the direct impression of aesthetic textures, which encourages the use of ornate details in architecture.

6. Mirrored Glass

Mirrored glass has a thin reflective coating, typically silver, applied uniformly on one side. Mirrored glass adds a sleek, modernist appearance amongst other glass varieties that is well-liked for use in display cases, retail spaces, automotive mirrors, medicine cabinets, cosmetic mirrors, decorative walls, and other applications. In addition to being functional, it adds aesthetic appeal.

Why Is It Used?

Mirrored glass has a visually appealing, highly reflective surface and selective one-way visibility. This is useful for a variety of applications, such as decorative walls in interior buildings, cosmetic mirrors, and scientific display cases that require both reflections and visibility. Normal transparent glass is made both aesthetically pleasing and functionally remarkable by the mirror coating.

7. Low E Glass

Low-emissivity glass, also known as Low E glass, reflects ultraviolet and infrared light while letting visible light pass through its thin transparent coating. As a result, indoor heat can be better retained during the winter and dispersed outside during the summer, due to improved insulation. Low-e glass is widely used for windows in residential and commercial buildings that are energy-efficient.

Why Is It Used?

Low-E glass uses advanced proprietary coatings to modify the inherent properties of glass for specific applications such as insulation or self-cleaning. This gives glass more capabilities than it could have with regular glass compositions, opening up new applications.

8. Coated Glass

Coated glass has layers of metal or mineral that are adhered directly to its surface to give it particular mechanical, chemical, optical, or thermal characteristics. Coatings can make glass heat-reflective, UV-resistant, electrochromic, self-cleaning, anti-glare, germ-resistant, and other properties. Common uses for coated glass include bulletproof glass for security, self-cleaning glass buildings, and transparent touch screens and displays.

Why Is It Used?

Coated glass is used to add unique qualities that ordinary glass lacks, such as heat reflection, self-cleaning capabilities, bullet resistance, UV blocking, scratch resistance, and antimicrobial qualities. The specialty coatings improve the optical, thermal, mechanical, and chemical properties of glass, making it suitable for different purposes.

How To Choose The Right Type Of Glass?

- Safety and Security: For applications where safety is critical (windshields, doors, etc.), use tempered or laminated glass which resist breakage and shatter into harmless pieces.

- Custom Optics: Use coated glass designed with the precise optical and surface properties required for specialised optics such as filters, displays, lenses, or touchscreens.

- Strength and Durability: Tempered glass, which is four to five times stronger than ordinary glass, should be used if the glass must endure strong winds, sudden temperature changes, or blunt force.

- Aesthetics: Use patterned glass with various textures, finishes, and colours for ornamental and decorative touches.

Mechanical Strength

| Glass Type | Product Standard | Mechanical Strength (5% Fractile) |

|---|---|---|

| Soda-Lime-Silicate Glass | EN 572-1 | 45N/mm2 |

| Heat Strengthened SLS Float Glass | EN 1863-1 | 70N/mm2 |

| Enamelled Heat Strengthened SLS Glass |

EN 1863-1 |

45N/mm2 |

| Heat Strengthened SLS Patterned Glass |

EN 1863-1 |

55N/mm2 |

| Thermally Toughened SLS Float Glass | EN 12150-1 |

120 N/mm2 |

| Enamelled Thermally Toughened SLS Glass | EN 12150-1 |

75N/mm2 |

| Thermally Toughened SLS Patterned Glass | EN 12150-1 |

90N/mm2 |

TRLV Permissible Glass Strength

| Glass Type | Permissible Stress (N/mm2) | ||

|---|---|---|---|

| Overhead Glazing | Vertical Glazing | ||

| Thermally Toughened Float Glass | 50 | 50 | |

| Thermally Toughened Patterned Glass | 37 | 37 | |

| Enamelled Thermally Toughened Float Glass* | 30 | 30 | |

| Heat Strengthened Glass | 29 | 29 | |

| Enamelled Heat Strengthened Glass* | 18 | 18 | |

| Annealed Float Glass | 18 | 12 | |

| Annealed Patterned Glass | 10 | 8 | |

| Laminated Annealed Float Glass | 22.5 | 15(25**) | |

STRUCTURAL USE OF GLASS

Additional recommendations for allowable stresses are provided in Structural Use of Glass [3], which defines values based on load type and glass type

| IStructE Permissible Glass Strength Values | |||

|---|---|---|---|

| Load Type | Load Example | Glass Type Allowable Stress (N/mm2) | Thermally Toughened |

| Annealed | Thermally Toughened | ||

| Short Term Body Stress | Wind | 28* | 59 |

| Short Term Edge Stress | Wind | 17.8* | 59 |

| Medium Term | Snow | 10.75 | 22.7 |

| Medium Term | Floors | 8.4 | 35 |

| Long Term | Self-Weight, Water, Shelves | 7 | 35 |

Conclusion

Glass is much more than just the clear substance that it first seems to be. Glass continues to elevate human progress through both grand and subtle use cases that impact lives and livelihoods, such as protecting smartphone screens, enabling smart window technologies, insulating buildings, and transporting solar energy. The above glass varieties continue to permeate almost every aspect of modern life.

FAQ’s:

- What is the most popular type of glass?

Float glass is the most popular type of glass due to its high optical clarity and versatility.

- What is the main difference between tempered and laminated glass?

Tempered glass is 4-5 times stronger due to internal compression, while laminated glass uses a vinyl interlayer to hold fragments together.

- Can insulated glass units really help reduce energy costs?

Insulated glass units with Low E coatings can cut building energy costs by 25-50% by increasing thermal insulation and preventing heat flow.

- What is smart glass and how does it work?

Smart glass has a unique polymer coating that, in response to a low voltage, can change from opaque to transparent, allowing for adjustable light transmission.